|

During 15 years, David has used a 600 scope. Eyepiece high with this scope was at about 2,8 m, like the 800 mm of this web site. Since we share some nights together observing with our scope, David began to be interested by their ease of transport and compact design. I'm always interested in drawing and making Dobson, so we found that a fast 600 was a good solution for him. I made the structure and he made the primary and secondary mirror. The focal of the previous scope was 2,8m and it's now 2m so the instrument is much more compact. It's now possible to observe at zenith using only a one or two step small ladder. I made the structure and he made the primary and secondary mirror. The primary mirror is a pyrex blank 53 mm thick. Focal ratio is F/3.3, Francon and Couder criteria are respected. The finish is ultrasmooth

The cage got only one ring in order to decrease wind sensitivity. Classical structure tends to be more shaky with a big top cage. This ring is made with a 9 mm thick birch plywood. It has been reinforced with carbon fabric. The spider is all inox made. It will not be black paint in order to avoid thermal problem. The secondary is 160 mm small dimension, and 22 mm thick.

|

|

The truss is made with 40 mm 1,5 mm thick pultruded carbon. Those tubes are very rigid. Aluminium inserts are glued at both extremity with epoxy glue. Top and low clamps system are made with plastic big head plastic screw and don’t required tools for setup.

The mirror box is made with plywood (9 mm birch) on 20 mm thick foam. The structure is very rigid. In order to save room during transport, bearings are detachable. Stainless steel bar are put on the fork when bearings are removed and during transport. They enable the mirror box to be slightly higher so the FRP bearing don’t touch Teflon pads and they can be put or remove with ease. It takes a minute to do the operation.

The cell is astatic. It has 12 points. 3 fixed points and 3 with triangles on top and levers under. In order to test new ideas, the lateral support are made with hard plastic wheels. The mirror is 53 mm thick, enough to have such a system according to the images the scope gives.

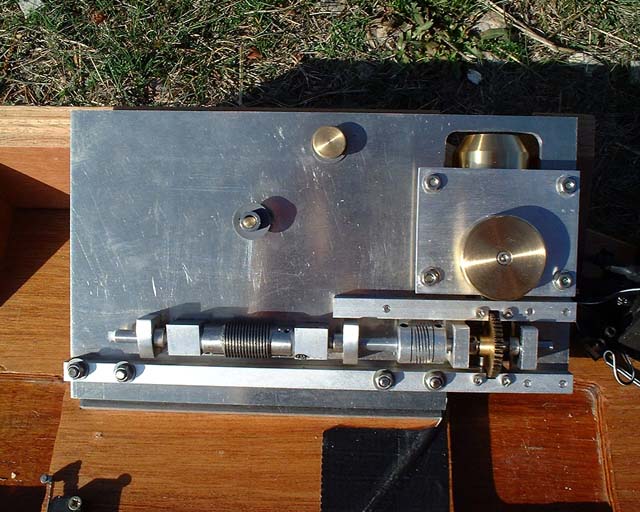

Fork is also made with a composite structure. Only front and rear panel are made with oak. The telescope is on an equatorial platform with about 1 hour of tracking. Equatorial platform mechanical parts have been made by Thierry Prevost.

|