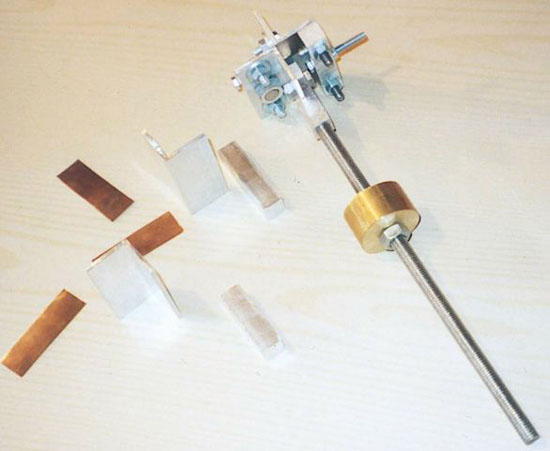

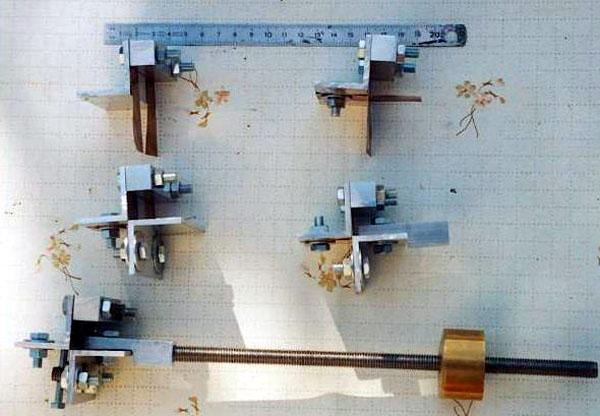

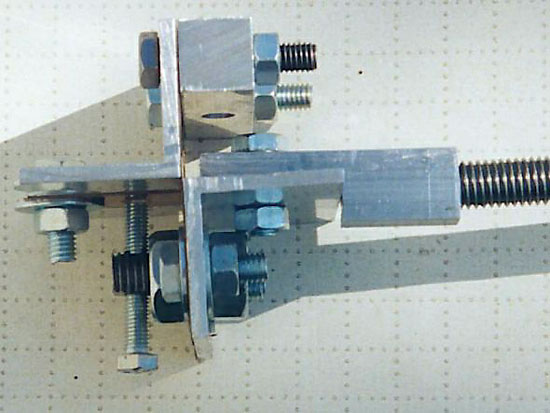

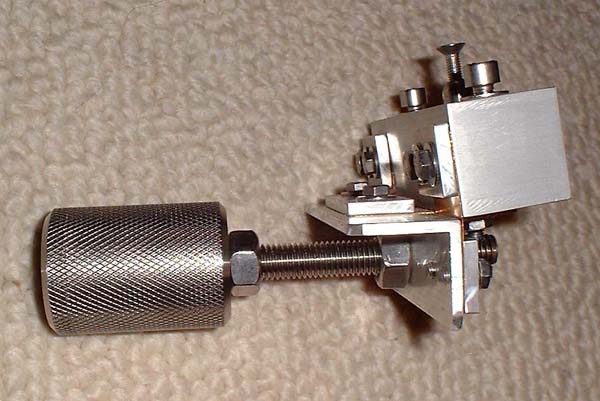

The search for a solution to reduce "the hysterese as much as possible” (“Mirror surface distortion”) is achieved, as much as possible, by the elimination of the friction transmitted from the levers to the mirror supports. The replacement of the piston used to transmit the effort of the counterweights by flexible blades can also be applied to the levers. The metal, chrysocal, is a special one and its use has been found to be of great value for this use. It is a variety of bronze whose elastic properties are remarkable. If one applies a force to the blade it returns exactly to the same position when the pressure is released. For this reason, blades of only 0.25 mm in thickness are appropriate. The range of adjustment is small but its use is remarkably simple to implement because the machining is all the parts is easier. A simple hacksaw can cut the aluminum "L" shape parts and some sheet metal shears can cut bronze. Holes can be drill using a simple drill press. Also, whatever the astatic mirror cell type is, if it requires the use of flexible blades, the chrysocal is metal of choice.

|

|

|

|

|

| This cell for a 32 inc mirror works well but levers will soon been rebuilt in order to accomodate eavier counterweight, necessary to have a better levers/counterweight ratio of about 1/5. Currently the counterweight's influence is too small. It balances the mirror weight but as it is light, the fact of move it along the axis don't have an influence big enough to enable an accurate tuning of the cell. Wider chrysocal blade will be use in order to accomodate eavier counterweight.

|

|

|

| see also |

|

|