Our machines at GAP47 |

|||

The first machine used by GAP47 was made when we had to polish our 20' mirror in 1992. The aim was to go through that phase of the work without excessive efforts, while retaining the characteristics and advantages of handwork (by limiting the defects coming from the repetitivity of mechanical movements). The principle that was chosen then was to opt for a pantograph which would increase muscular power. |

|||

|

|||

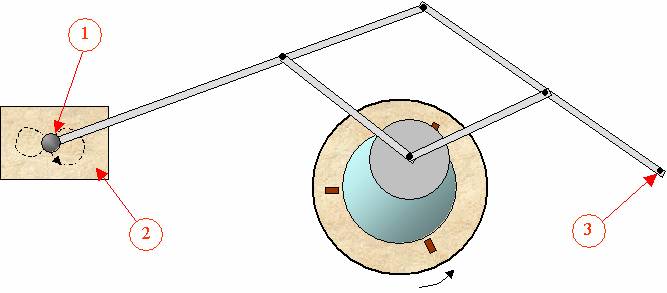

The pantograph's arms are linked to one another by pin articulations. One end consists in a fixed pivot (3) . At the far end of the pantograph there is a handle (1) and a small wheel that may be rolled over a small table (2) . At the central articulation of the device there is a drive pin which transmits the movements to the lap. It is impossible to use this system with the mirror on top. The revolving table (supporting the mirror) is run by a 220v AC motor coming from an old supermarket cash desk conveyor belt. The speed of the mirror is 10 rpm and cannot be changed. There is a pedal to keep the motor running. |

|||

The second machine built at GAP47 is more recent (2006). It is an off-set Hindle-type machine with a double crank system. It will be used for the polishing of our current project of a 16' mirror, and, as far as possible, for its figuring. Here are the principles that were paramount in its building : |

|||

|

|||

|

|||