|

Technical review

How

to select a tube HF amplifier ? (III)

Power

supply

After

the vacuum tube(s) the next most expensive component of a power

amplifier is the high voltage (HV) power transformer. If the use of

russian tubes can decrease the price of your amplifier, technically

speaking it is very hard to reduce the price of wires, coils and

magnets, and therefore the power supply unit (PSU) remains the stumbling block of your budget.

The

amplifier PSU has to be designed to provide

the required power. The requirements and therefore the design of the

amplifier will differ from small audio amplifiers specs to power amplifiers

(kW-class).

The power efficiency of

such an amplifier being important, this factor has effects on its sizes,

weight, power consumption and dissipation. This last requests special devices for cooling

and to respect the thermal stability of the amplifier.

Transformers As

shows very well the picture of the Emtron

DX-2SP displayed above as well as closeups displayed below,

transformers are the most cumbersome elements of an amplifier, the

heaviest too. Such

transformers are about 20x15x10 cm in size (8x6x4") and their weight exceeds

20 kg (40 lbs.) ! Therefore some manufacturers send the PSU separate from the

amplifier itself, to the amateur to made the assembling.

A

transformer is just a piece of iron with a pair of wires coiled

wounded around it - one with many more turns in the coil than the

other. The coils of wire are not physically connected. In the

largest power transformers the iron core can be immersed in an

insulating oil bath which does not conduct electricity well.

How

works a transformer ? Basically a conductor, such as a copper wire,

is sitting in a magnetic field that is changing, and thus a current

will flow in the conductor. This current will not be steady but will

also be changing. Alternatively, if a changing current is present, it will

produce a changing magnetic field of 50 or 60 Hz.

A transformer works only with alternating current (AC)

circuits. The AC current enters the primary coil. A magnetic field

is produced that is concentrated in the iron core of the

transformer. A secondary coil of wires (also conductors) is wrapped

around the iron core, not physically touching the first set of

wires. The changing magnetic field produced by the first coil is

experienced by the second coil and current begins to flow in these

wires as well. The second coil has many more turns of wire and

offers a higher resistance to the current flow than the first coil.

The greater resistance means that a larger voltage drop (than is

present across the first coil of wire) is produced from one end of

the coil to the other. Therefore a low voltage enters the

transformer and a high voltage exits, or vice versa.

Most

transformers operate at high efficiency transmitting about 99% of

the power that enters them. About 1% of the power is lost in heating

the transformer.

|

|

|

|

CV

Ferroresonant transformer |

Control

transformer |

Class

2 transformer |

|

There

are many kinds of

transformers : audio, class 2, CV-ferroresonant,

power isolation, control, flyback, pulse, encapsulated, sense

transformers, autotransformers, switchmode, inductors/chokes,

toroids, current transformers, 3 phase transformers, power factor

correction, high voltage, and more. In radio applications the

ones that interest amateurs are mainly inductor/choke transformers,

toroids and power transformers. Their specifications vary depending

the application and power requirements. Don't be surprised to find

in kW power amplifiers one or more toroid transformers of about 10

cm diameter and 4 cm high or a big one 22 cm diameter and 8 cm high.

The "small" one weighs about 5 kg, the larger exceeds 12

kg.

Plate

supply

An

HF amplifier used at legal limit needs a distinct plate transformer separate from

the filament transformer and control power supply. The plate supply should be

able to handle 1.5 kW continuous in any mode. In full key-down CW ouput for example, a 3 kV plate supply

should be able to sustain 700 mA. A plate

supply capable of this DC current in a B+ line should have a filter capacitor

bank of about 60µF, with a surge voltage no less than 1.41 times

the peak plate voltage.

|

|

|

All

a compartiment, so half the volume of this QRO

HF-2500DX amplifier is dedicated to the power

supply and its circuits boards. At left, inserted

between the high grade electrolytics capacitors and

the control boards is the HV rectifier board. We can

see the twenty N5408 rectifier diodes that provide

5000 PIV capacity for DC smoothed and filtered by the

eight electrolytic capacitors located below. At right,

above the HV rectifier is the control board. It

provides LV bias, screen trip and control circuitry.

The smaller circuit board mounted at right is the

screen supply board. |

|

Rectifier

board

A full wave bridge rectifier

board in the plate supply is a must. This HV rectifier board contains some dozen rectifier

diodes (N5408) in a bridge arrangement, providing for a 3kV plate PS a total voltage rating of 5

kV PIV for DC smoothed, and filtered by several high grade electrolytic

capacitors.

Electrolytics

capacitors

The

best electrolytics are the ones that can endure years of heat in an

amplifier. So they can be top grade, as the ones used in computers, or

even oil filled models. Like tubes, it is essential to place them in a

well ventilated cabinet fixed on an insulated bracket.

|

|

|

|

|

At

left, inside a Ranger 811H amplifier we discover the

PSU in the upper right part showing the EHT

capacitor stack mounted on a board. Below are two

toroidal transformers of about 5 kg each. At center

the filter capacitors (116mF,

3.6 kV) attached to the PSU of an Emtron

DX-3 amplifier. At right, in this QRO

HF-2500DX the electrolytics capacitors are located in

the left compartment. |

|

Bleeder

resistors

A

bleeder resistance is a resistance connected across the output

terminals of the power supply. Its functions are to discharge the

filter capacitors as a safety measure when the power is turned off

and to improve voltage regulation by providing a minimum load

resistance. The time lapse required to drain the high charge of the

power supply can vary from a fraction of a second to several

hours in worst cases... Contrarily to the past where amplifiers used

filter chokes and large bleeder resistors drawing 10% of full load

current on the power supply to dissipate all the heat, modern

amplifiers needs only a bleeder able to draw barely 1% of the load

once the amplifier shut down. To meet this requirement a resistance of

100-500 KW across the entire

filter bank will do that job. There are two possibilities : either

using individual resistors ranging from 68-75 KW

3-5 watts each or a single power resistor of 100-200 watts depending on the resistance.

|

|

|

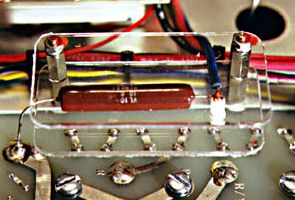

The

glitch resistor installed in the Heathkit SB-200 power amplifier. |

At

last to prevent any overheating and shorten the capacitors life span,

it is recommended to mount the bleeder resistors away from the capacitors

bank.

Glitch

resistor

As

all powered devices, an amplifier can always be subject to a surge. AC

line fuses are far to offer sufficient protection against current limits.

Therefore a glitch resistor is recommended in series with the HV lead,

even is some amplifiers have an electronic plate over-current

circuit. Made of vitreous enamel insulated wire-wound type this

resistor acts either as a "fuse" and will explode in

opening the circuit to protect the power supply or as a barrier

against current. It the first case it is recommended to use a 0.68

ohm 1-2 watts resistor in serie in the B+ line and in the second

case a 50 ohm 50 watt power resistor to limit the B+

current; this latter has for function to not "fuse".

Wiring

At

last, examining how wires are attached and how connections have been soldered in an amplifier you can

immediately recognize the sign of a quality material manufacturer.

Avoid amplifiers in which wires looks like a mesh or which circuits

show dark or too large soldering, extended-wrap connections and wires

of too small size, sign of amateur work. On the contrary choose a model

in which wires are thick, and the wiring circuit well laid out, solderings

bright, tie-wrapped. The connection to the other modules should be made via

a wire loom, and grounded to the chassis.

For

security purposes wires constituing the AC primary should be at least

#12 AGW in size (inner Ø2.07 mm), while the HV wiring should be

made of heavy Teflon or silicone rubber insulated, and no less than

#18 AGW in size (inner Ø1.16 mm).

|

|

|

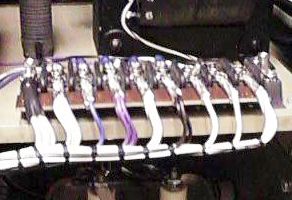

At

left, the wiring in the power supply compartment of the QRO

HF-2500DX Mark III amplifier. This section is

totally separate from the RF compartment with a

stainless steel pane. Teflon dominate in this high

quality amplifier. At right, the wire loom of a Henri

Radio amplifier. Does your actual amplifier shows

a similar quality ? |

|

Shielding

All

sections of an amplifer, the PA stage, Pi-network, controller

circuits, power supply unit, etc should be totally insulated and

enclosed in individual shielded compartment within the amplifier

chassis. Power lines and control leads should enter these shielded

enclosures via feed-through capacitors.

In

the RF section all interconnect wiring should be made of coaxial or

shielded wire. "RF" and "non-RF" wires

have also to be separate and never be found

side by side in the same area. "RF" wiring for example

should be isolated in its unit away from the other wires, like

should be the full Pi-section to avoid side effects due to RFI. RF

interconnecting cables should have their braiding grounded at shield

entry points. Lead dress should be used.

These

protecting measures will maintain RF integrity, minimise internal RF

feedback, and ensure regulatory electromagnetic compatibility (EMC)

compliance.

Last chapter

Security

issues

|